At the intersection of space exploration and electronic manufacturing lies a critical challenge: ensuring hardware reliability in the harshest environment known to humanity. This success story highlights how our engineering team’s expertise and flexible manufacturing capabilities helped a customer prepare their mission-critical hardware for space deployment through specialized manufacturing processes.

The Challenge: Space-Grade Hardware Requirements

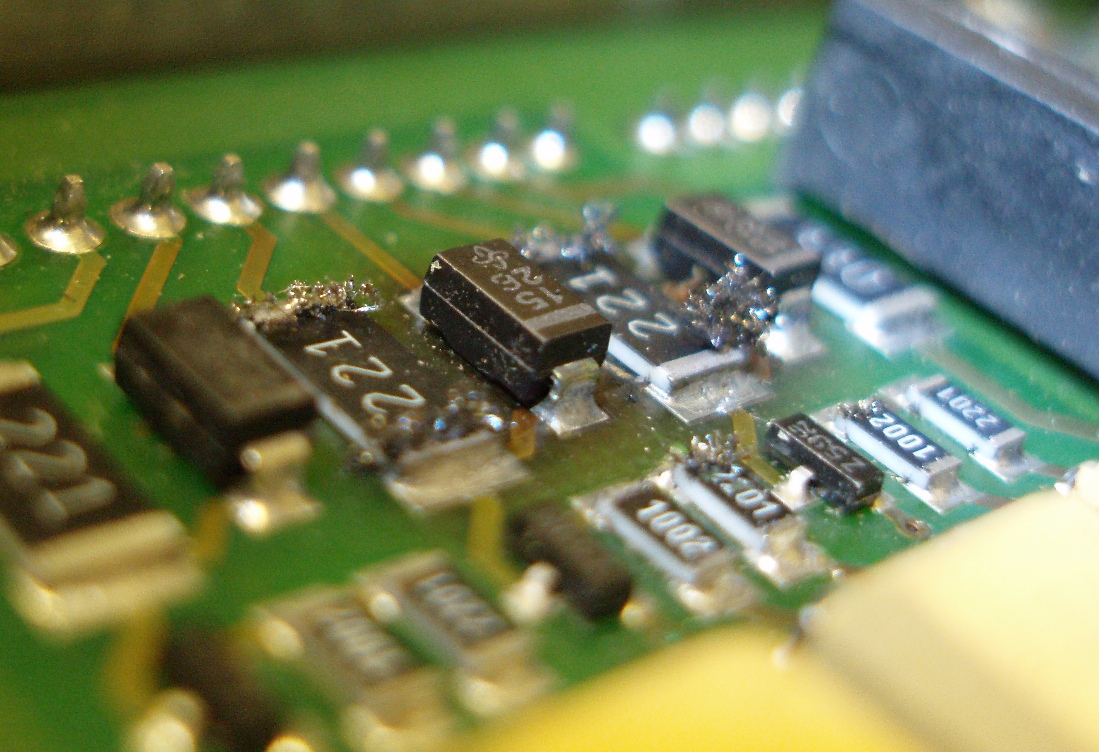

Our customer approached us with a unique requirement for their space mission: they needed our SOM1-SOC boards manufactured using lead-based solder instead of the industry-standard lead-free alternatives. While this might seem like a straightforward request, it represents a complex engineering challenge rooted in a critical reliability concern: tin whisker formation.

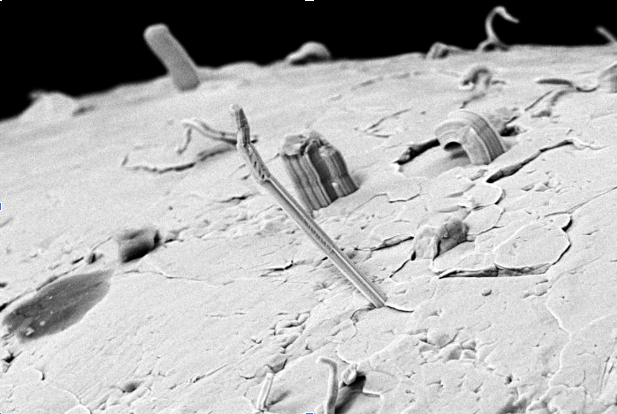

Understanding Tin Whiskers: A Critical Space Hardware Concern

Tin whiskers are microscopic, crystalline structures that can grow from surfaces where tin is used as a plating material or in solder joints. These filamentary growths, often thinner than a human hair, can reach lengths of several millimeters and pose a severe threat to electronic systems, particularly in space applications.

The Formation Process

Tin whiskers form through a complex metallurgical process involving:

- Internal stresses within the tin plating or solder

- Temperature fluctuations

- Environmental factors such as humidity and pressure

- Mechanical stress on the components

In space applications, the vacuum environment and temperature cycling can accelerate whisker growth, making this phenomenon particularly concerning for space-bound hardware.

The Impact on Electronic Systems

These whiskers can cause catastrophic failures in electronic systems through several mechanisms:

- Short Circuits: When whiskers grow long enough to bridge adjacent conductors, they can create short circuits, leading to system failures or erratic behavior.

- Debris Damage: Broken whiskers can become conductive debris inside sealed components, potentially causing short circuits or mechanical interference.

- Current Carrying Capacity: Despite their small size, tin whiskers can carry significant current before burning out, making them capable of creating persistent short circuits.

Why Lead-Based Solder is Preferred for Space Applications

Lead-based solders, particularly the traditional Sn63Pb37 (63% tin, 37% lead) composition, offer several advantages for space applications:

Whisker Mitigation

The presence of lead significantly reduces the tendency for whisker formation. Lead atoms interrupt the crystalline structure that enables whisker growth, making lead-based solders inherently more reliable in this aspect.

Mechanical Properties

Lead-based solders provide:

- Better fatigue resistance

- Superior thermal cycling performance

- Improved mechanical strength

- Lower melting point, reducing the thermal stress on components during assembly

Proven Track Record

Lead-based solders have a long history of successful use in space applications, with documented reliability in extreme environments.

Our Manufacturing Solution

To meet our customers’ requirements, we developed a comprehensive manufacturing process that involved several complex steps:

Component Preparation

- Removal of existing lead-free solder balls from BGAs and other components

- Careful reballing of components with lead-based solder

- Inspection and verification of reballing quality

Process Development

- Recalculation and optimization of thermal profiles for lead-based solder

- Development of specialized cleaning procedures

- Implementation of enhanced inspection protocols

Manufacturing Implementation

- Set up of a dedicated lead-based solder manufacturing line

- Implementation of stringent quality control measures

- Comprehensive testing and verification procedures

The Complex Engineering Behind Reballing

The reballing process deserves special attention as it represents one of the most technically challenging aspects of this project. This process involves:

Solder Ball Removal

- Precise temperature control to remove existing solder balls without damaging the component

- Specialized tools and techniques to ensure the complete removal of lead-free solder

- Careful cleaning and preparation of the component surface

Reballing Process

- Precise placement of new lead-based solder balls

- Controlled reflow process with optimized thermal profile

- Multiple inspection points to ensure quality

Quality Verification

- X-ray inspection of reballed components

- Mechanical testing for ball attachment strength

- Electrical testing to ensure functionality

Beyond Hardware Manufacturing

This project exemplifies our commitment to being more than just a hardware manufacturer. We are a comprehensive solution provider with expertise across multiple domains:

Hardware Design and Manufacturing

- Custom design modifications for specific requirements

- Specialized manufacturing processes

- Rigorous testing and validation

Firmware Development

- FPGA algorithm implementation

- Custom firmware development

- Optimization for specific applications

Software Solutions

- Host system software development

- Embedded system programming

- Integration and testing services

Mechanical Design

- Custom enclosure design

- Thermal management solutions

- Environmental protection systems

Successful Outcome

Through careful engineering and precise execution, we successfully manufactured the SOM1-SOC boards to meet the customer’s space-grade requirements. The boards passed all quality control checks and were certified ready for space deployment, demonstrating our ability to handle complex manufacturing challenges.

The Importance of Specialized Manufacturing

This project highlights the critical importance of specialized manufacturing capabilities in the space industry. While lead-free solder has become standard in most electronic manufacturing, space applications often require different approaches to ensure reliability. The ability to modify standard processes and implement specialized solutions is crucial for supporting advanced applications in aerospace and other demanding fields.

Looking Forward

Our engineering team remains committed to helping customers achieve their most complex requirements. Whether it’s specialized manufacturing processes, custom design modifications, or complete system solutions, we have the expertise and capabilities to deliver results that meet the most demanding specifications.

Conclusion

This success story demonstrates our ability to go beyond standard manufacturing processes to meet specialized requirements for space applications. Our comprehensive understanding of electronic manufacturing challenges, combined with our broad expertise in hardware, firmware, and software development, makes us an ideal partner for complex technical projects.

We continue to invest in our capabilities and expertise to support customers across various industries, particularly those requiring specialized solutions for challenging environments. Our commitment to understanding and solving complex technical challenges sets us apart as a true solution provider rather than just a hardware manufacturer.