Why Quality Standards Matter

In the world of electronic manufacturing, quality isn’t just a preference; it’s a requirement. IPC, the Association Connecting Electronics Industries (originally known as the Institute for Printed Circuits), has developed a comprehensive suite of standards—such as IPC-A-610, IPC-J-STD-001, and IPC-A-600 that guide manufacturers in producing reliable, high-performance electronics. Among these are the IPC “classes,” which define different levels of workmanship and inspection criteria based on the end-use application. These standards form the backbone of quality assurance across the electronics industry. These standards, known as IPC classes, serve as the backbone of electronic manufacturing quality assurance, ensuring that electronic products meet specific performance and reliability requirements.

What Are IPC Classes?

IPC classes are quality standards that categorize electronic assemblies based on their intended application and required reliability levels. These classes are defined primarily in IPC-A-610 “Acceptability of Electronic Assemblies,” which focuses on the acceptability of electronic assemblies. Other related standards include IPC-A-600 for bare boards, IPC-6012 for rigid PCBs, and IPC J-STD-001 for soldering processes.

These classifications help manufacturers determine the appropriate level of quality control, inspection criteria, and manufacturing processes needed for different types of electronic products. The standards cover everything from component placement and soldering quality to documentation requirements and testing procedures, with each class defining specific criteria for what constitutes Target, Acceptable, and Defect conditions.

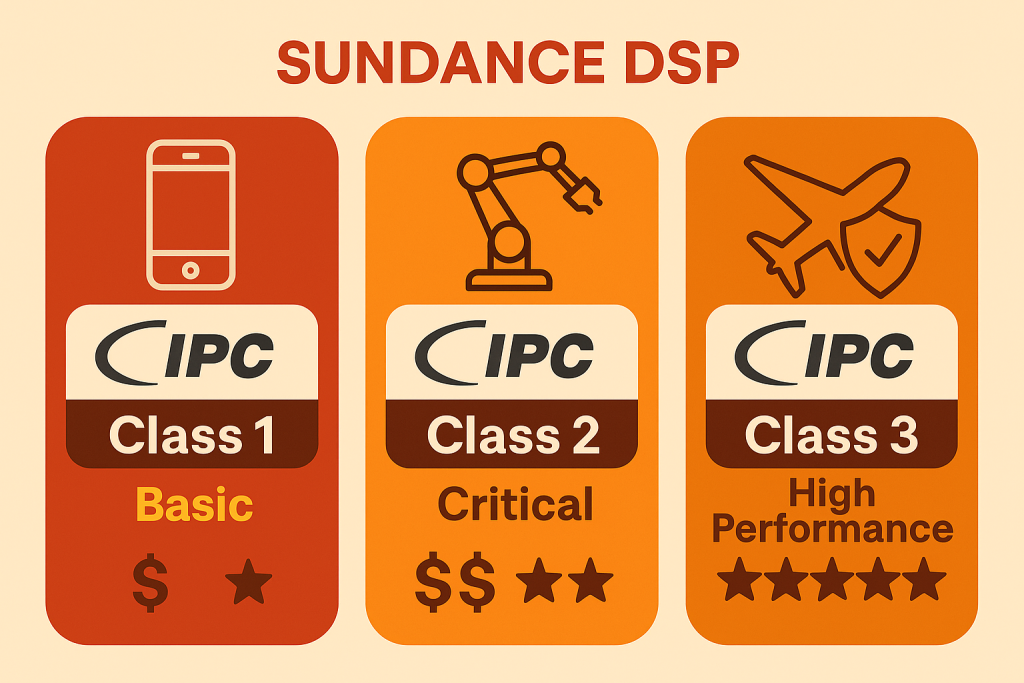

The Three IPC Classes Explained

IPC Class 1: General Electronic Products

IPC Class 1 represents the most basic level of electronic assembly standards, designed for general electronic products where the primary requirement is basic functionality.

Characteristics:

- Minimum quality standards for basic functionality

- Limited cosmetic requirements

- Basic soldering and assembly standards

- Minimal inspection requirements

- Lower reliability expectations

Typical Applications:

- Consumer electronics with short lifecycles

- Non-critical entertainment devices

- Basic appliances

- Toys and novelty items

Quality Focus: Class 1 prioritizes cost-effectiveness over long-term reliability, making it suitable for products where replacement is more economical than extensive quality assurance.

IPC Class 2: Dedicated Service Electronic Products

IPC Class 2 represents the standard level for most commercial and industrial electronic products, balancing quality, reliability, and cost-effectiveness.

Characteristics:

- Enhanced quality standards beyond basic functionality

- Improved cosmetic requirements

- More stringent soldering and assembly criteria

- Regular inspection protocols

- Extended service life expectations

- Better documentation requirements

Typical Applications:

- Computer systems and peripherals

- Telecommunications equipment

- Industrial control systems

- Automotive electronics (non-safety critical)

- Commercial test equipment

- Standard military equipment

Quality Focus: Class 2 ensures reliable operation over extended periods while maintaining reasonable manufacturing costs, making it the most common standard in commercial electronics.

IPC Class 3: High-Performance Electronic Products

IPC Class 3 represents the highest level of quality standards, designed for applications where continued performance is critical and failure cannot be tolerated.

Characteristics:

- Maximum quality standards with zero-defect objectives

- Strict cosmetic and functional requirements

- Rigorous soldering and assembly standards

- Comprehensive inspection and testing protocols

- Maximum service life and reliability expectations

- Extensive documentation and traceability requirements

- Enhanced materials and component specifications

Typical Applications:

- Aerospace and avionics systems

- Medical life-support equipment

- Military and defense systems

- Nuclear power plant controls

- Safety-critical automotive systems

- High-reliability telecommunications infrastructure

- Space applications and satellites

Quality Focus: Class 3 prioritizes absolute reliability and performance over cost considerations, ensuring mission-critical applications operate flawlessly throughout their service life. Class 3 requires assemblies to meet stricter criteria, often aiming for ‘Target’ conditions in solder joints and cleanliness, whereas lower classes may accept ‘Acceptable’ conditions that still meet functional requirements.

Why Higher IPC Classes Matter

Enhanced Reliability

Higher IPC classes implement more stringent quality controls that significantly reduce the probability of failure. This enhanced reliability is crucial for applications where system failure could result in safety hazards, mission failure, or significant financial losses.

Extended Service Life

Products manufactured to higher IPC standards typically exhibit longer operational lifespans due to superior materials, processes, and quality assurance measures. This extended service life often justifies the higher initial investment through reduced replacement and maintenance costs.

Improved Performance Consistency

Higher-class standards ensure more consistent performance across production runs and throughout the product’s operational life. This consistency is essential for applications requiring predictable behavior and precise specifications.

Risk Mitigation

By adhering to higher IPC standards, manufacturers significantly reduce the risk of field failures, warranty claims, and potential liability issues. This risk mitigation is particularly important for companies operating in regulated industries or safety-critical applications.

Regulatory Compliance

Many industries require compliance with specific IPC classes for regulatory approval. Higher-class standards often facilitate easier compliance with industry-specific regulations and standards.

Manufacturing Process Differences

The manufacturing processes vary significantly between IPC classes:

Component Selection: Higher classes require components with better specifications, tighter tolerances, and enhanced reliability ratings.

Soldering Standards: Class 3 demands perfect solder joints with specific fillet requirements and no cosmetic defects, while Class 1 may accept minor cosmetic imperfections that don’t affect functionality. Class 2 falls between these extremes with moderate cosmetic requirements.

Inspection Protocols: Higher classes implement more frequent and comprehensive inspection procedures, including automated optical inspection (AOI), in-circuit testing (ICT), X-ray inspection for BGA/QFN solder joints, functional testing (FCT), and conformal coating inspection when applicable.

Documentation: Class 3 requires extensive documentation and traceability throughout the manufacturing process, including full serialization, component lot tracking, version-controlled manufacturing process records, and complete product genealogy tracking. This level of traceability allows Class 3 products to meet aerospace, medical, and other regulatory traceability requirements.

Environmental Testing: Higher classes often mandate additional environmental stress testing to verify performance under extreme conditions, including thermal cycling, vibration testing, and humidity exposure.

Defect Classification: IPC-A-610 categorizes defects differently for each class. What might be acceptable in Class 1 (such as minor solder bridging that doesn’t affect functionality) would be rejected in Class 3.

Process Controls: Class 3 manufacturing requires more stringent process controls, including tighter temperature profiles for reflow soldering, controlled atmosphere requirements, and more frequent calibration of equipment.

Cleaning and Coating Requirements: Class 3 products may require post-assembly cleaning to remove flux residues and prevent corrosion, as well as conformal coating (per IPC-CC-830) to protect against moisture, dust, and chemicals in harsh environments.

Supply Chain Standards: Class 3 compliance involves certified suppliers, use of RoHS/REACH-compliant materials when applicable, and IPC training/certification for operators and inspectors to ensure consistent quality execution.

SundanceDSP’s Commitment to IPC Class 3 Excellence

At SundanceDSP, we understand that our customers depend on our products for mission-critical applications where failure is not an option. This understanding drives our unwavering commitment to manufacturing all our boards according to IPC Class 3 standards—the highest quality classification available.

Why We Choose Class 3

Mission-Critical Applications: Our boards are frequently deployed in aerospace, defense, telecommunications, and industrial applications where system reliability directly impacts mission success and safety.

Performance Assurance: Class 3 manufacturing ensures that our boards deliver consistent, predictable performance throughout their operational lifetime, meeting the demanding requirements of high-performance applications.

Long-Term Value: While Class 3 manufacturing requires higher initial investment, it delivers superior long-term value through reduced failure rates, extended service life, and minimal maintenance requirements.

Cost Considerations: While Class 3 manufacturing typically costs 15-30% more than Class 2 due to enhanced materials, additional testing, and stricter process controls, the long-term value proposition often justifies this investment for critical applications.

Training Requirements: Personnel working on Class 3 assemblies typically require additional certification and training to ensure they understand the stricter requirements and quality expectations.

Customer Confidence: Our Class 3 commitment provides customers with confidence that SundanceDSP products will perform reliably in their most demanding applications.

Our Class 3 Implementation

Zero-Defect Manufacturing: We implement comprehensive quality control measures designed to achieve zero-defect production objectives.

Advanced Materials: All components and materials used in our boards meet or exceed Class 3 specifications for reliability and performance.

Rigorous Testing: Every board undergoes extensive testing protocols, including functional testing, environmental stress screening, and burn-in procedures.

Complete Traceability: We maintain complete documentation and traceability for all materials, processes, and test results, including serialization, component lot tracking, and version-controlled manufacturing records that meet aerospace and medical regulatory requirements.

Advanced Inspection Methods: Every board undergoes a comprehensive inspection using multiple techniques, including AOI, X-ray inspection for hidden solder joints, functional testing, and conformal coating verification when applicable.

Continuous Improvement: Our quality management system continuously monitors and improves our processes to maintain the highest standards of excellence.

Conclusion

Understanding IPC classes is essential for making informed decisions about electronic product quality and reliability requirements. While higher IPC classes require greater investment in materials, processes, and quality assurance, they deliver superior reliability, performance, and long-term value for demanding applications.

SundanceDSP’s commitment to IPC Class 3 manufacturing reflects our dedication to providing customers with the highest quality DSP solutions available. By adhering to these stringent standards, we ensure that our products meet the demanding requirements of mission-critical applications while delivering the reliability and performance our customers expect.

When selecting electronic components for critical applications, choosing manufacturers committed to appropriate IPC standards is not just recommended, it’s essential for project success and operational safety. The investment in higher quality standards pays dividends through improved reliability, reduced maintenance costs, and enhanced system performance throughout the product lifecycle.